Medium Density Fiberboard is mainly used for internal usage applications, in part due to its inadequate moisture resistance. It is accessible in raw form with a finely sanded exterior or with decorative coats such as wood veneer, melamine paper, or vinyl.

These fibers are then mixed with a synthetic resin, typically urea-formaldehyde or phenol-formaldehyde, and compressed under high pressure to form a dense, flat panel. MDF boards are popular in the construction and furniture industries because of their consistent density, smooth surface, and versatility.

What Is MFD Board?

MDF stands for Medium Density Fiberboard. It is a type of engineered wood product made from wood fibers, combined with a synthetic resin and formed into panels under high pressure and temperature. MDF boards are made from wood fibers that are extracted from different types of wood, such as pine, spruce, or eucalyptus.

Medium Density Fiberboard is a wood material prepared by separating the softwood or hardwood residuals into the wood fibers, frequently in a defibrillator, wax mixing and forming a shape-like a panel by using high pressure and temperature.

Read More: What is Gypsum Board & Its Application in Construction

MDF Properties

The following most favorable MDF properties to be used for work.

Density: Medium-density fiberboard (MDF) is recognized for its uniform density, providing a consistent and stable material. This uniformity contributes to its reliability in various applications, ensuring that the material maintains its structural integrity across the entirety of a given project.

Smooth Surface: One of MDF’s standout features is its fine particles, resulting in an exceptionally smooth and flat surface. This characteristic makes MDF an ideal choice for applications where a polished appearance is desired, such as painting, veneering, or laminating.

Machinability: MDF’s composition allows for easy cutting, shaping, and machining. Woodworkers and craftsmen appreciate its versatility, enabling them to create intricate designs and detailed woodwork with precision and relative ease.

Dimensional Stability: MDF exhibits excellent dimensional stability, meaning it experiences minimal expansion or contraction in response to changes in temperature and humidity. This property is crucial, as it ensures that MDF maintains its shape and structure over time and in different environmental conditions.

Versatility: Suited for a broad spectrum of applications, MDF finds common use in furniture, cabinetry, molding, and interior trim. Its versatility arises from a combination of properties, including its smooth surface, machinability, and consistent density.

Screw Holding Capacity: MDF offers good screw-holding properties, allowing for secure fastening in various assembly methods. This feature enhances its suitability for construction and woodworking projects where stability and durability are paramount.

MDF Board Thickness is between 2 – 35 mm and the width is 4 ft.

- Modulus of rupture

- Modulus of elasticity

- Thickness

- Elasticity

- Water absorption

- Swelling

Uses of MDF Board

MDF Board can be very easily cut, shaped, and painted because of its smooth properties.

The following are the most popular uses boards,

1. Furniture

The board is to manufacture various furniture products used by many companies. For example, you can purchase a bookshelf and TV furniture made up of a board. There are proven to be economical compared to pure wooden furniture products.

Furniture manufacturing by the use of fiberboard are cheaper and their manufacturing cost is lower compared to other product.

These are popular furniture materials as their manufacturing cost is lower than ready-made types of furniture.

2. Cabinetry Use of Board

The board is most popularly used in house interior carpentry cabinetry work.

There are lots of cabinets you will find that are made of board and which are covered with laminated wood at the top.

House furniture like cabinets of kitchens and units of shelving is manufactured from the board. It is also used for molding work, Door framework, and laminated wooden flooring.

3. Fire Resistance

Some peoples are not aware of the fact that boards are actually provided fire protection because it possesses good quality fire resistance properties.

The recent construction trend to use fire resistance materials for building construction is growing rapidly.

There are various types of MDF materials used to construct business buildings, office buildings, and other trade buildings.

4. Vapour Repulsion

The boards are used as insulation and obstacle to vapors in many commercial as well as residential buildings.

This fibreboard is manufactured such that it can deal with moisture for a long time and shrinkage-free drying process without any rotting effect on it.

These boards are resistant the moisture entry into the house, therefore less heating is required in the house and ultimately reduces the electricity bill.

5. Soundproofing

It is not a known fact but boars can also work as a sound barrier in-house. It will help to reduce the noise level in the home.

There are many sound speaker manufacturing companies that utilize the MDF board in their product because it absorbs sound and reduces internal vibration.

The boards are also used in offices, newsrooms,s and building flats for reducing the noise level in space.

6. Roofing

Fibreboard is most popular used in home roofing systems as it possesses good quality weather resistance. These boards are proofing to the best material to use for shingles backing of different roof types.

It can be used for wall sheathing work of the home interior. Fibreboard is a flexible and durable material used in home exterior and interior work decoration.

Read More: Fire Resistant Materials Used in Construction

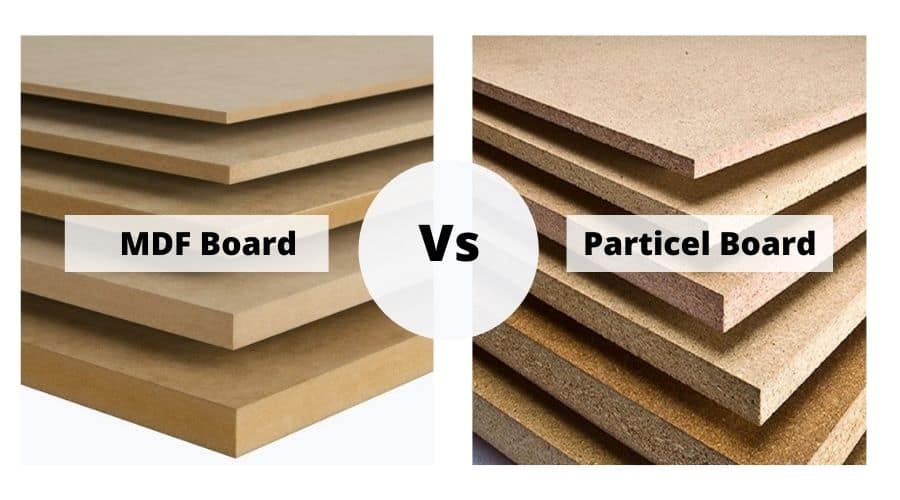

Particle Board vs MDF

The following is the comparison between MDF vs Particle Board

| MDF | Particle-board | |

| Look | The board has a shiny finish and smoothness properties because of the gains of wood that are used of the same size. | It does not provide a shiny and smooth surface. |

| Density | The board has a greater level of density compared to particleboard. | Its low density compares to |

| Strength | The board is less strong compared to Particle Board. | Particle-board is not very strong as MDF Board |

| Durability | The board is durable and long-lasting material compared to particleboard. | Particleboards are less long-lasting and durable compared to |

| Weight | The board is Heavy | Less Heavy |

| Moisture | It is resistant more compares to particleboard | Less resistance |

| Lifespan | Lifespan is more than 10 years | More than 25 years |

| Price | Its costlier materials | Cheap |

Read More: 35 Types of Wood With Pictures & Use

m where they are loaded into the trucks as per the necessary quantity.

MDF Board Advantages

Following are the MDF Wood advantages,

- Medium Density Fiberboard possesses economic value to common people as it is reasonable at cost and economical. So, they are within everyone’s capacity to purchase.

- Medium Density Fiberboardsaves the trees as it is a recycling procedure.

- It is simple to take any color where wood carries long tenure for staining several colors

- Medium Density Fiberboarddoes do not possess knots or kinks which disturb the smooth and shiny surface.

- Medium Density Fiberboard is protected from some insects as some chemicals are utilized for the processing of MDF.

- It can be painted or shaded and given a look almost the same as natural wood. So, it can replace the position of wood furniture.

- Depiction on Medium Density Fiberboard is simpler than on wood.

- To give Medium Density Fiberboard look like natural wood veneers, laminators may easily be connected to it.

- The strong, dense, flat, stiff Medium Density Fiberboard is a decent choice rather than wood.

- Medium Density Fiberboard has no grain as it is not a real product, it is easy to cut, and drill without any damage.

- It has outstanding machining character its adequate density.

MDF Wood Disadvantages

The following are the disadvantages of MDF wood,

- A board has poor strength compared to wood. Material made up of boards has less life.

- Medium Density Fiberboard can break or slash under excessive pressure.

- Medium Density Fiberboard soaks water quicker compare to wood.

- Driving screws and nails on a board is not easy.

- Medium Density Fiberboard is made of VOC, including urea-formaldehyde, which can enter the lungs and eyes and become a reason for irritation.

- The board cutting spread lots of dust in the air which is can cause damage to the lungs and make breathing difficult for a human.

Read More: How to Remove Stain from Wood (Best 9 DIY Tips & Tricks)

Cost Of MDF Board

| No. | Medium Density Fiberboard | Thickness | Price |

| 1. | Decorative Medium Density FiberboardBoard | 1.9 mm to 25 mm | Rs. 52 / Square feet |

| 2. | Laminated Medium Density FiberboardBoard | 2.5 mm to 25 mm | Rs. 42 / Square feet |

| 3. | Laminated Medium Density FiberboardTeakwood | 2.5 mm to 25 mm | Rs. 42 / Square feet |

| 4. | Pre Laminated Medium Density FiberboardBoard | 2.5 mm to 25 mm | Rs. 42 / Square feet |

| 5. | LaminatedMedium Density Fiberboard | Size – 9 x 6 | Rs. 42 / Square feet |

| 6. | Medium Density FiberboardPre Laminated Board | – | Rs. 51.63 / Square feet |

You Might Also Like:

Reviving Opportunities: How to Generate and Convert Expired Listing Leads in Real Estate

Sample AI Prompts Every Novice Designer Should Know – Masterpieces Made Easy

Types Of Roof Insulation Materials

7 Easy Tips To Keep Your House Clean And Organized

40 Types Of Tables: Choose Best For Home

Epoxy Paint: Exploring Its Features, Differences from Normal Paint