What Is Pointing?

Pointing is a technique of strengthening and repairing brick masonry or stone masonry mortar joints. In case when old mortar joints crack and disintegrate, then the defective mortar is removed by hand or power tool and replaced with fresh mortar, preferably of the same composition as the original.

There are various types of pointing in construction Flush Pointing, Weathered Pointing, Keyed Pointing, V-Grooved Pointing, Beaded Pointing, Struck Pointing, Recessed Pointing, and Tuck Pointing.

Purpose of Pointing

The pointing work not only protects the mortar joints from the adverse effect of the atmosphere but also improves the appearance of the wall by proving the pattern of the joints, their thickness, colors, and texture prominently.

In the case of externally exposed masonry work joint is considered the weakest and most vulnerable spot from which rainwater or dampness can enter.

Read More: Brick Masonry Vs Stone Masonry – Which Is Better?

Mortar Used For Pointing

Pointing work is usually done with lime mortar or cement mortar.

- Lime mortar for pointing work is done by equal parts of fat lime and fine sand and then grinding the mixture thoroughly, in a mortar mill.

- Cement mortar for pointing work is prepared by mixing cement and sand in proportion of 1:2 or 1:3.

Method of Pointing In Construction

Following are the steps to be followed while doing pointing work.

- Old mortar from the joint is ranked out to a depth of at least 20mm for better bonding.

- Remove all dust from masonry joints by using wire mesh.

- Wash the joint surface with clean water and kept it wet for a few hours.

Fill the mortar in these joints in the desired shape to cover all joint space.

- Press the mortar into joints with a thin trowel still; it sticks to the old mortar surface.

- Complete all joints similarly. The water curing must be done for at least three days if a lime mortar is used and ten days if cement mortar used

Read More: 14 Types Of Brick Bond And Their Advantages

Types of Pointing

Following are the usual types of pointing in construction,

- Flush Pointing

- Weathered Pointing

- Keyed Pointing

- V-Grooved Pointing

- Beaded Pointing

- Struck Pointing

- Recessed Pointing

- Tuck Pointing

1. Flush Pointing

In the flush pointing, the mortar filled and pressed into a mortar joint. After that, it is finished off flush with the edges of the bricks or stones, to give a smooth appearance. Then the final finish is given by trimming the edges neatly with a trowel and a straight edge.

Flush pointing is also done by wiping over the finished pointing with the trowel or piece of rough cloth.

- It does not make a good appearance.

- But it is durable as it aborts the chances of accumulation of dust, water, etc.

- It is the most popular type of pointing used in building construction.

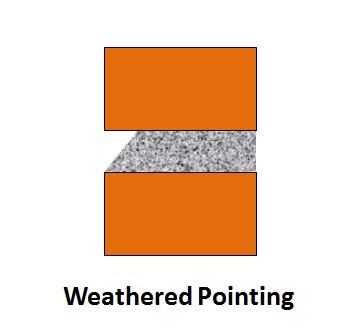

2. Weathered Pointing

In Weathered Pointing the mortar is pressed into a joint, and while the mortar is still fresh the top of the horizontal joints is neatly pressed back by 3-6 mm with the pointing tool. They look like sloping from the top of the joint to the bottom of the joint.

3. Keyed Pointing

In these Keyed pointing the mortar is pressed into joints by trowel and well finished off with the face of the masonry surface. After that, the joint is pressed back by small-diameter steel lengthwise (6 mm dia). It will form a curved arc groove into a mortar joint. The vertical joint also finishes similar manner.

In this type, mortar is first pressed into joints

- A semi-circular curve-type notch is formed by a tool or small steel bar.

- These types of points are providing an excellent appearance to the wall.

- Keyed pointing are mostly used for superior-type work, particularly for vertical joints of walls.

Read More: 7 Brick Test To Decide Quality Of Bricks

4. V-Grooved Pointing (V Pointing)

V pointing is similar to keyed pointing work. The mortar filled and pressed into a joint. After that, the V-shaped groove is formed in the joint by the use of V shape tool.

5. Beaded Pointing

In Beaded Pointing, the mortar is pressed into a masonry joint and concave grooves are formed into a joint by using a steel tool having a concave shape. Beaded pointing gives an excellent appearance to the mortar joint but is liable to get damaged quickly.

6. Struck Pointing

In this pointing, the mortar is first filled and pressed to match the face of brick masonry work, and then the top edge of the joint is pressed inside around 10 mm compared to the bottom corner. It will form a slope from top to bottom so that that rain wall will drain off quickly.

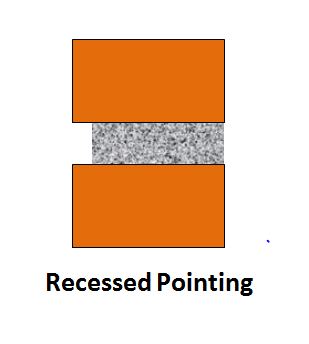

7. Recessed Pointing

These pointing are generally not suitable for buildings in exposed situations because they do not readily shed water.

- Recessed pointing’s are by pressing mortar back from edges by 5 mm or more.

- The pressed pointing face is kept vertical

- It is advisable to use only bricks with excellent frost resistance should be used with recessed joints.

- It Gives a good appearance.

8. Tuck Pointing

- In these pointing the mortar joint is filled and pressed to the level surface of masonry.

- While the mortar is still fresh, grooves are cut in the mortar joint. The slot size of 5mm in width and 3mm in depth. Ti is then filled with white cement putty and kept projecting beyond the face of the joint by 3 mm. in case these projections are done in a mortar then it is called bastard pointing or half tuckpointing.

Advantages of Pointing work

Pointing work of brick masonry is the most effective way of restoring the condition and physical appearance of a building structure, and it forms an essential part of overall and ongoing building maintenance.

The following are the advantages of pointing work,

- Improve structure integrity of the building structure.

- Provide weatherproof external walls.

- Restore overall building appearance.

- Maintain or significantly increase the overall value of your home or property

- Reduce any ongoing maintenance on your brickwork

Disadvantages of Pointing in Construction

- Pointing work can be time taking process.

- It requires skilled labour.

- The pointing can be easily deteriorate due to weathering action.

Conclusion

In Conclusion pointing is a crucial aspect of masonry and brickwork which involves filling and finishing the joints between bricks or stones for enhancing their appearance, weather resistance, and durability.

There are various types of pointing techniques available, each offering unique characteristics and visual effects, firstly beaded pointing is a method where a thin bead or rope like shape of mortar is formed along the joint, this technique creates a neat and consistent appearance, adding a decorative touch to the brickwork.

Struck pointing is often employed in more rustic or informal settings as it gives a slightly rougher texture and emphasizes the natural character of the masonry, it also helps to shed water effectively, reducing the risk of water ingress and promoting the longevity of the brickwork.

You May Also Like:

How Mobile Apps Enhance Field-to-Office Communication

Tensile Strength of Concrete Test: Exploring Split Cylinder Test and Tensile Strength Test Procedure for Concrete Evaluation

40 Types of Bridges

Types Of Resilient Flooring: A Durable Coverings Materials

How Changing Tax Laws Impact Construction Companies: What You Need to Know

How Many Cubic Feet In a Yard of Concrete