As a structural engineer or site engineer, we frequently work with various types of designs and details. One word, “development length,” or the denotation “Ld,” is mentioned in the drawing.

Do you understand what “development length” means? Where should development length be provided and why should we supply it?

as well as how to determine development length.

What Is the Development Length?

To achieve the appropriate bond strength between steel and concrete, the minimum length of the steel bar needs to be firmly attached to the column.

The strong link between column-to-footing and column-to-beam structural elements is caused by development length.

In buildings, we are aware of how to shift loads. The weight travels from the slab to the beam, then the beam to the column.

The column to the footing, and finally the footing to the ground. We must verify the component joints in order for this cycle to function properly.

Read More: When Do You Need Steels for Property Builds and Refurbishments?

Why Provide Development Length?

The developments length serves as a hook. As a result, there are fewer chances that the bars on a concrete beam may slip under a heavy load from the structure.

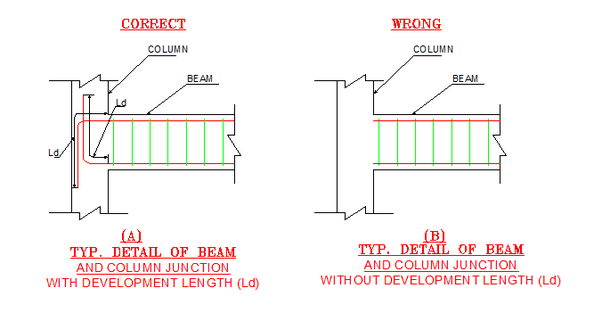

Imagine what would happen if we did not provide adequate developments length in structure. Images of the same scene with and without developments length are shown above.

Because concrete cannot withstand tensile stress, steel is added because it can. There is a danger that a beam or slab will slip from the connection if the concrete is bound without developments length because it will appear to be externally attached to a column.

Additionally, if the structure collapses, the bars won’t be damaged; instead, they will merely separate from the column component.

We all have carried a bag at some point in our lives, for instance. What transpired, then, if the palm was open? Without a doubt, you won’t be able to carry the bag, and if you do, there’s a good risk it’ll escape if you carry it in your open hand.

What can you then do? You can form a “U shape” with your palm-like hook. Similar to this, we create development length using steel bars.

A crucial part is played by the joint that connects the superstructure and the substructure in smoothly transferring the weight.

Therefore, joints need to be really strong and connect to one another in order to create a very strong framework.

What Did We Need to Calculate Development Length?

1. Grade of steel bars

2. Grade of concrete

3. Diameter of steel bar

4. Type of steel bar

Read More: How To Calculate Steel Quantity | Steel Quantity Formula

How to Calculate Development Length?

Once we have all of the necessary information, we can quickly determine the development length. Typically, we choose a developments length of 50D or 40D at random.

However, as it is a rule of thumb, this value is not precise. If we use a large diameter, an additional bar will be very expensive.

Note: The length of development varies for tension and compression. People typically assign the same importance to both stresses.

There are several bar types, and as there are various bar numbers, there are various calculations.

- Calculation of development length of plain bars(compression, tension)

- Calculation of development length of deform bars(compression, tension)

- Calculation of development length of bundled

Calculation of development length of plain bars(compression, tension)

- Ld: – development length

- ɸ: – nominal diameter of the bar

- σs: – stress in bars, design load

- τbd: –design bond stress

The following equation appears in the IS code (26.2.1). Now that we have all of the answers to the equation above, we can define nominal diameter as the diameter of the steel bar that needs to be bent.

Steel bars are valued by the stress they contain. The stress permitted in bars is Fe410, and Fe500, where 500 is the maximum acceptable stress.

Is the code on line 26.2.1.1 contains the design bond stress and other information about the design bond? From grade to grade, it differs

The ultimate developments length will be obtained once all values have been entered into the equation.

Where (τbd: – design bond stress) for tension in beam and slab

| Grade of concrete | M20 | M25 | M30 | M35 | M40 and above |

| τbd | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 |

The above table is referenced in IS 456.2000, where all bd values for tension are provided. Additionally, if the component is a compression member, the value will be 25% higher than it was originally when it was a tensile component.

Always choose 1.2 if the grade is lower than the M20 grade of concrete.

Where (τbd: – design bond stress) for compression in beam and slab

| Grade of concrete | M20 | M25 | M30 | M35 | M40 and above |

| τbd | 1.5 | 1.75 | 1.875 | 2.125 | 2.375 |

Calculation of development length of Deformed bars(compression, tension)

The equation is the same as above the difference is in τbd value only.

Where (τbd: – design bond stress) for tension in beam and slab

The value of the design bond stress in a deformed bar is 60% greater than the value of the design bond in a plain bar. for arousal.

| Grade of concrete | M20 | M25 | M30 | M35 | M40 and above |

| τbd | 1.92 | 2.24 | 2.4 | 2.72 | 3.04 |

The value of the design bond stress in a deformed bar is 25% greater than the value of the design bond in a plain bar. due to compression

| Grade of concrete | M20 | M25 | M30 | M35 | M40 and above |

| τbd | 2.4 | 2.8 | 3 | 3.4 | 3.8 |

Example,

We have one beam where the diameter of the bar is 20 mm, the steel we use is fe500 and the concrete grade is M25. So, find the development length for both compression and tension.

Solution:

- Nominal diameter of bar: – 20

- stress in bars, design lode: – 500 N/mm2

- design bond stress: – 1.4(tension) , 1.75(compression)

Put the above values in the equation of development length.

Td = 20×500 / 4×1.4

Td = 1785 mm(tension)

Td = 20×500 / 4×1.75

Td = 1428 mm(tension)

So, both values are different.

Factors Affecting Development Length

- The compressive strength of concrete is inversely related to the development length of the steel bar. As a result of the high concrete strength, the development length is short.

- Since density is another crucial element, the length of the development will increase as we use lightweight concrete.

- Development length decreases as clear cover is increased.

- The coating of bars also impacts length of development. Because concrete and steel surfaces can be separated.

- The length of development is directly impacted by steel bar diameter. The development length is also short because of the small diameter.

Read More: Steel Fiber Reinforced Concrete

You May Also Like:

- When Do You Need Steels for Property Builds and Refurbishments?

- Steel Fiber Reinforced Concrete | Mix Design | Advantages and Disadvantages of SFRC

- How To Calculate Steel Quantity | Steel Quantity Formula | How to Calculate Steel Quantity from Drawing | BBS of Slab | Steel Quantity Calculation

- What Are Steel Piles | 4 Types of Steel Piles | Corrosion of Steel Piles Steel | Advantages and Disadvantages of Steel Piles Foundation

- 10 Different Types of Steel | Carbon Steel & Alloyed Steel

Bed Alternatives: 13 Best Alternatives To Bed For Small Spaces

Unit Weight of Steel Bar: Steel Bar Weight, Formula

Running a Civil Engineering Team? Here’s How to Make Your Team Meetings Go More Smoothly

Types of Aggregates And Their Uses

How to Keep House Cool in Summer Naturally (12 Tips)

20 House Cleaning Tools and Equipment | Housekeeping Tools